Industry news|2022-02-15| admin

The coupling is mainly used to transmit the power and motion of the drive shaft to the driven shaft and the load. It can absorb the deviation, shock, vibration and noise between the drive shaft and the driven shaft, and can also cut off the drive shaft on special occasions. Generated heat and microcurrents.

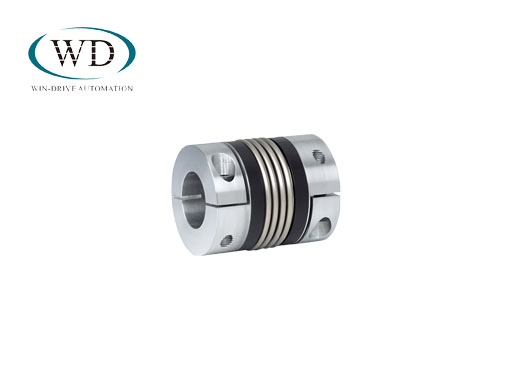

The types of couplings include bellows, plum blossom rubber, diaphragm type, coupling shaft, integrated slit, flexible coupling, etc., and can also be customized according to customer needs.

The following aspects need to be considered when selecting the coupling; speed, torque, and locking method.

Most of the coupling products on the market are now standardized or standardized. What are the precautions for the selection of various coupling products? To understand the selection of the coupling, you can first understand the relevant common sense according to the following common sense points.

According to the size of the load to be transmitted and the installation accuracy of the two parts connected by the concavity and convexity of the shaft speed, the selection of the coupling can be divided into the following processes:

1. Clear the size and nature of the load to be transmitted and the requirements for the buffering and vibration-damping function of the coupling

Gear couplings are generally used for high-power and heavy-duty transmissions, and highly elastic couplings such as tire couplings are generally used for transmissions that require severe shock loads or to eliminate torsional vibration of the shafting;

2. The working speed of the coupling is uneven and the centrifugal force caused by it

For high-speed transmission shafts, couplings with high balance accuracy should generally be used, and the more common ones are diaphragm couplings. Generally, slider couplings with eccentricity should not be used for such use requirements.

3. The magnitude and direction of the relative displacement of the two axes

After the adjustment of the device, it is difficult to maintain the strict and precise alignment of the two axes, or the two axes will have a large additional relative displacement during the operation. Generally, flexible couplings should be used, such as slider couplings. In the case of large radial displacement, the angular displacement or the connection of the two intersecting axes generally use universal couplings, etc.

4. Coupling reliability and working environment

Couplings made of metal components that do not require smoothness are more reliable than couplings that require smoothness. The function of coupling products that require smoothness will be affected by the smoothing effect and there is a certain probability of polluting the environment. Couplings made of non-metallic components such as oil-containing rubber are relatively sensitive to temperature corrosive media and strong light, and are relatively easy to age.

5. Coupling production, installation and protection costs

On the premise that the functions of use are satisfied, the selection of coupling products should be as far as possible to choose couplings that are easy to disassemble, simple to maintain and low cost. General rigid couplings, general non-metallic element couplings such as elastic pin couplings, plum blossom elastic couplings, etc., have good comprehensive performance and are ideal for small and medium power transmission.

The standard speed of the German R+W couplings represented by Shenzhen sz-windrive Automation is basically 10,000 rpm. The maximum speed of some models can be as high as 120,000 rpm after dynamic balance; the maximum torque of R+W bellows can reach 10,000Nm , the maximum torque of plum blossom rubber can reach 25000Nm; the locking methods include flange type, clamping type, separate clamping type, tapered clamping, outer clamping ring, tapered shaft, tapered expansion shaft, independent flange connection Wait. Coupling selection related knowledge welcome to consult!